ZJZ0540 casting pouring manipulator with ladle

ZJZ0540 casting manipulator for Foundry

Rotate 360°

Ladle capacity 500kg

Working radius 4m

Product Specification

| Product | Specification Model | Rated lifting capacity | Minimum lifting height of ladle | Maximum lifting height of the ladle | Maximum working radius | Rotation angle | Note |

| Hydraulic Pouring Manipulator | ZJZ0540 | 500kg | The main shaft of the ladle is initially parallel to the ground(Customized according to the customer's requirements) | 1100mm | Center of the column is 4000mm away from the small rotation axis | main unit rotates 345° lifting device rotates 360° | Including1setofPLCsystem |

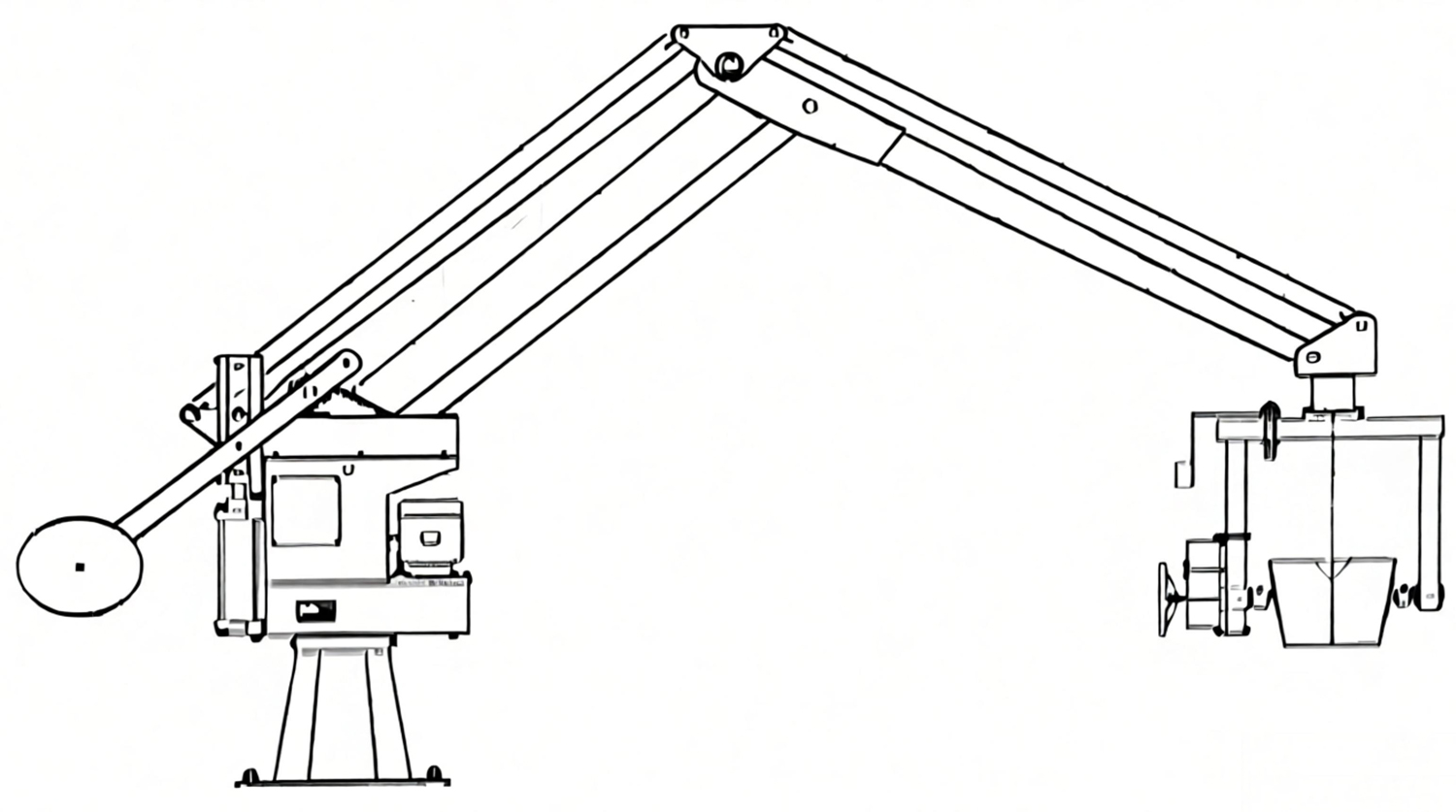

Casting manipulator structure

Product features

1) Pouring manipulator lifting mechanism is remotely controlled and can rotate 360° freely.

2) Casting manipulator machine adopts the principle of a four-bar linkage mechanism. Each mechanical arm can operate and stop at any angle to achieve a balanced stationary state. This significantly reduces the difficulty for operators during the pouring process, especially when dealing with risers and molten iron. It aims to reduce physical strain and improve the pouring speed and efficiency.

3) No limit switches are required. The limit is achieved by the oil cylinder's own stroke. The lifting of the arm is driven by the up and down movement of the piston rod, and a buffer device is set up, resulting in small impacts and stable operation.

4) Safety devices are installed in the hydraulic system. They have a safety protection function in cases of overload and other situations, preventing the occurrence of easily damaged components and accidents.

5) The PLC system can control the opening time of the pump and valve, as well as the adjustment of the flow output. This makes the system operation more stable.

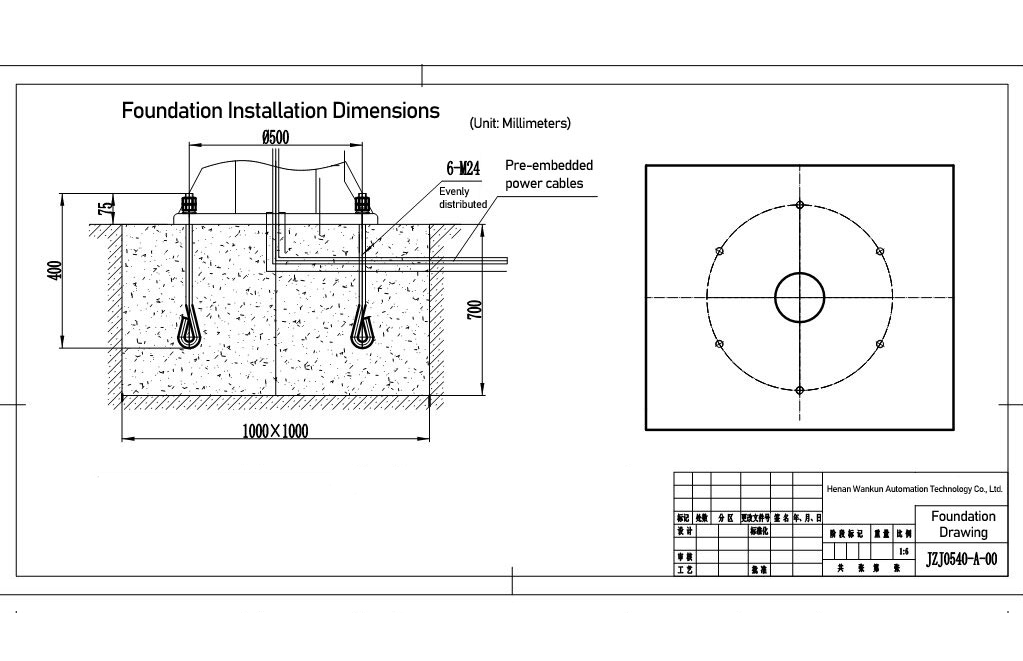

Foundation Installation Dimensions

Technical Requirements

1) All dimensions in this drawing are measured in millimeters.

2) The compressive strength of the foundation soil shall not be less than i ton per square meter

3) The specific position of the electrical cabinet and the pipelines connected to it shall refer to the overall power pipeline layout drawing.

4) The wire conductor (3-phase 5-wire system) has a cross-sectional area of 4 square milimeters, with a voltage of 380V + 220V, and 2.5 meters exposed.