Five advantages of Jib Crane: Why Can It Improve Material handling Efficiency

In busy workshops, warehouses or docks, are you troubled by frequent and short-distance material handling? Jib Crane perfectly solves the above problems. Its core purpose is to solve the problems of efficiency and safety in material handling. Especially in scenarios with limited space and frequent lifting, it replaces manual operations and realizes precise, efficient and low-risk material flow.

In simple terms, the main reasons for using cantilever cranes can be summarized as: providing unparalleled efficiency, flexibility and cost-effectiveness within a limited and specific working area.

Main types and applications

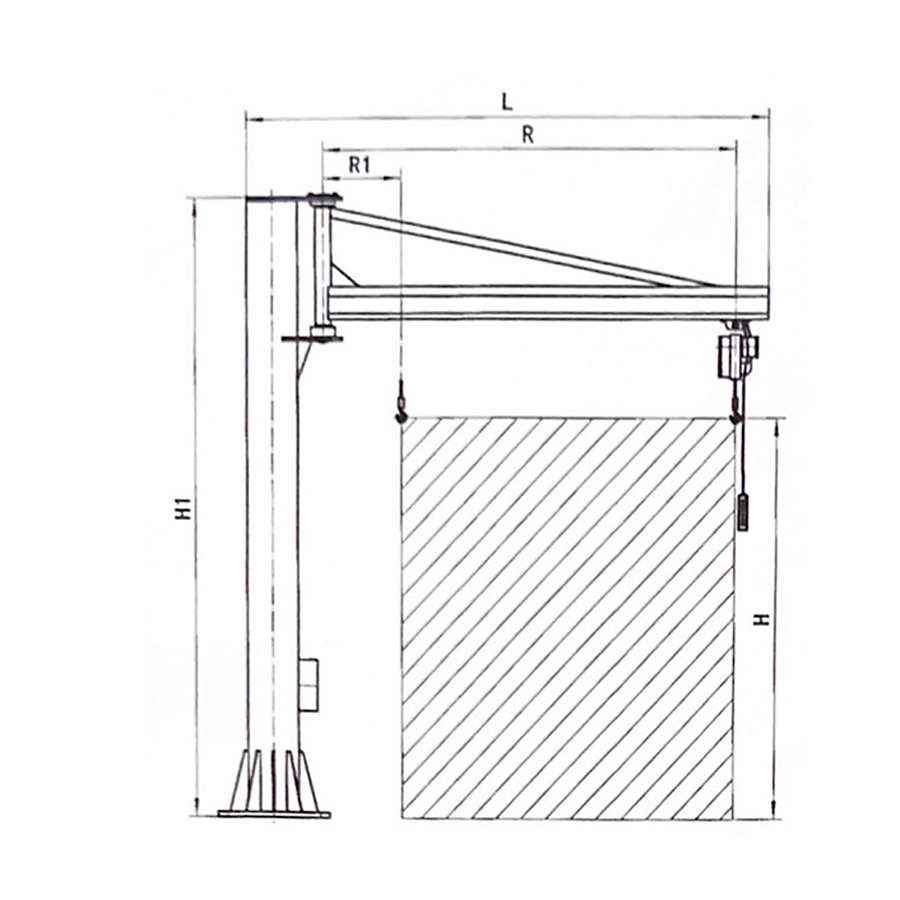

column cantilever crane

Fixed-point material handling and assembly work along beside production lines.

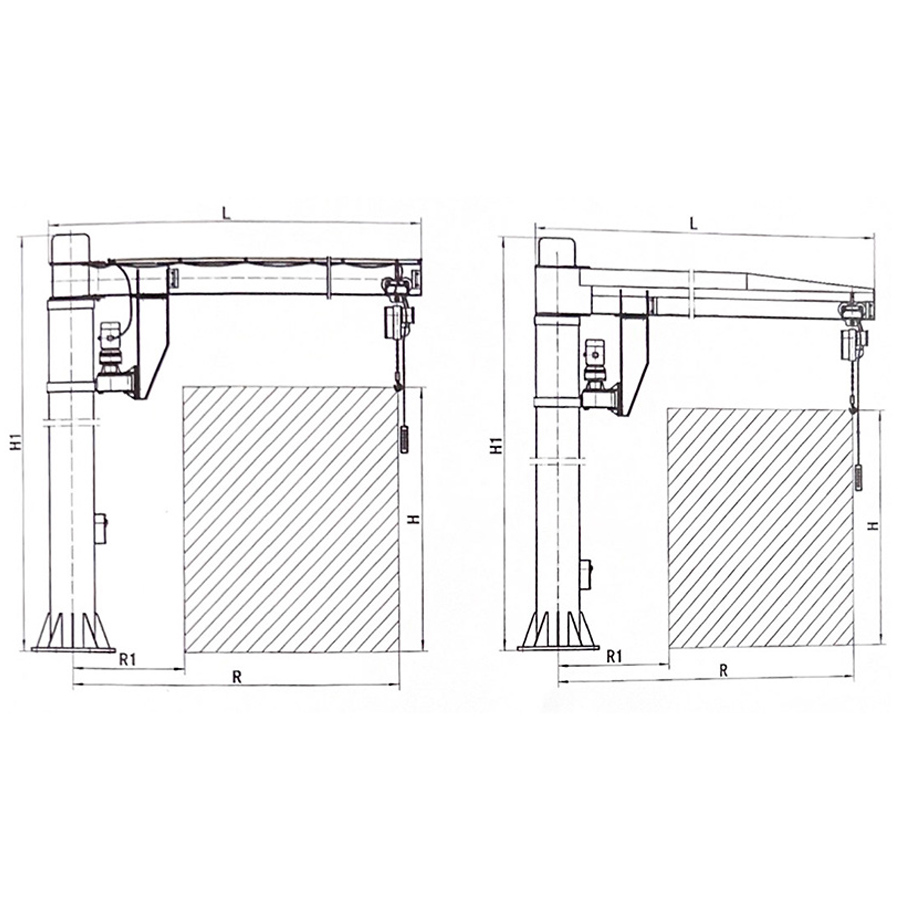

Base-type jib crane

Docks, outdoor sites, or the central area of factories, used for loading and unloading vehicles or serving multiple workstations.

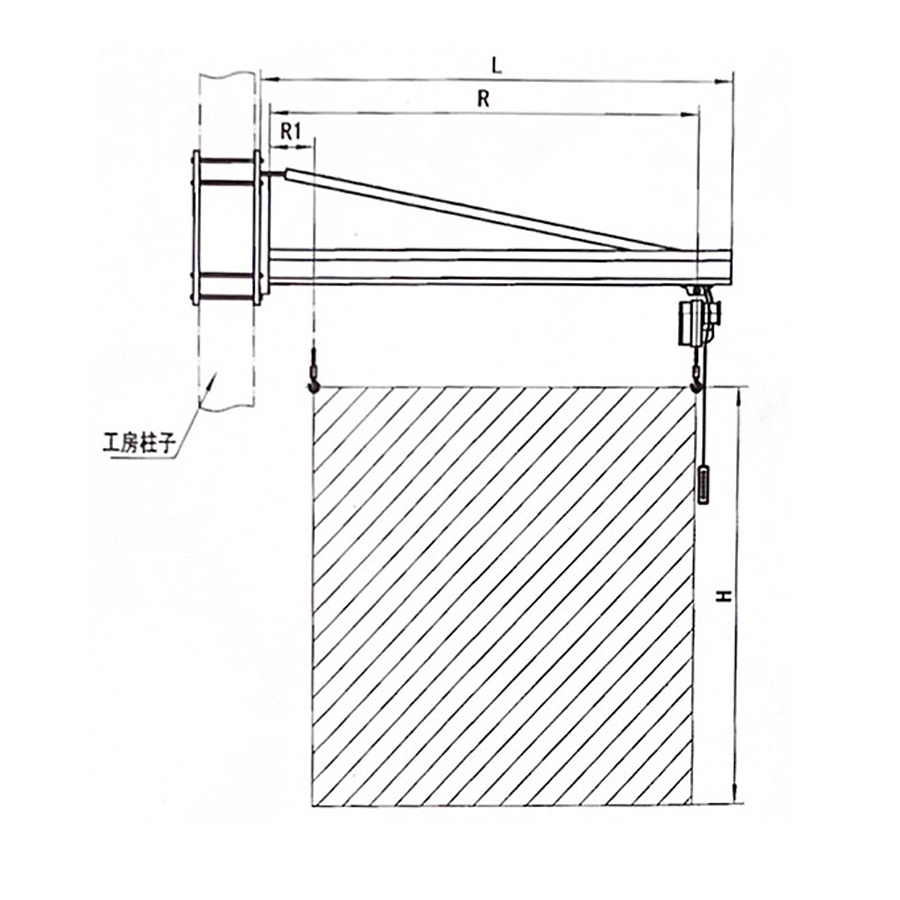

Wall-mounted crane

Extremely narrow aisles or corners, suitable for the handling of light goods.

Why use jib crane

Solve the transportation problem in space-constrained scenarios

Vertical and horizontal spatial coverage

Solve the problem that bridge cranes require track support and occupy a large amount of upper space; The problem that forklifts require wide aisles and are difficult to operate in dense production lines or narrow warehouses.

Column-type design: The base occupies a small area (usually ≤1m²), can be installed against the wall or beside equipment, and free up ground space.

360° rotating cantilever: Covering a circular area with a radius of 3 to 10 meters, it can complete multi-station material lifting without moving equipment.

Technical principle: The folding boom cantilever crane can reduce the vertical height by folding the boom, making it suitable for workshops with a floor height of no more than 4 meters, while traditional cranes require a clear height of no less than 6 meters.

Improve the efficiency and accuracy of material handling

Improve the efficiency and accuracy of material handling

Optimization of high-frequency short-distance handling to solve the problem that manual handling takes 5 to 10 minutes each time and forklifts need to repeatedly adjust their positions, resulting in low efficiency.

Electric rotation + lifting: The single lifting time is shortened to 1-2 minutes, making it suitable for high-frequency scenarios such as material replenishment on production lines and parts distribution on assembly lines.

Millimeter-level positioning: Controlled by servo motors and encoders, the stop error of the lifting gear is ≤±3mm, meeting the requirements of precision processing.

Multi-station collaborative operation

Technical principle: One cantilever crane can serve 3 to 5 adjacent workstations. By rotating the cantilever, it enables rapid material flow and reduces the idle rate of equipment.

Reduce labor intensity and safety risks

Replace high-risk manual operations and solve the problems of muscle strain and frequent falls and collisions caused by manual handling of heavy objects.

Electric assist system: It offsets the weight of heavy objects through counterweights or electric hoists, with an operating force of ≤50N (approximately 5kg force), allowing employees to operate it easily.

Integration of safety devices

Overload protection: Automatically shut down when the load exceeds the rated value.

Limit switch: Prevents the cantilever from rotating or lifting over the limit.

Anti-collision sensor: Emergency braking after detecting obstacles.

Technical principle: In high-temperature, corrosive or radioactive environments, personnel can be isolated from the hazard source through remote control operation.

Five core advantages

It offers fan-shaped or circular work coverage, allowing one device to serve multiple workstations.

By enhancing production efficiency, reducing work-related injuries and labor demand, the return on investment is extremely high.

Can achieve millimeter-level fine-tuning, allowing the workpiece to be smoothly and accurately positioned, thereby enhancing the quality of the final product.

Electric hoists or wire rope hoists can be configured as required, with a load-bearing range from 125 kilograms to 5 tons, compatible with precision instruments and heavy workpieces.

The structure is highly open, and key components (such as steel wire ropes and bearings) are easy to inspect and replace. Daily maintenance only requires one person per hour.

Consider four points when making a choice

Lifting capacity

Rotation radius

Installation environment

Lifting height

When should the use of Jib cranes be considered?

The working area is fixed and concentrated.

Frequent and repetitive material handling and positioning are required.

It is hoped that the intensity of manual handling can be reduced and production efficiency can be improved.

The working space is limited, so it is necessary to save floor area.

The budget is limited, but an efficient and reliable lifting device is needed.

The bridge cranes in the workshop are either too busy or unable to cover all corners.