Types of jib cranes

A lifting device with a crossbeam extending like an arm to achieve material hoisting and transportation. One end of the cantilever is fixed to the column or wall, while the other end is freely suspended and equipped with an electric hoist lifting device. During operation, it can rotate around the fixed point, covering a fan-shaped or circular working area. In industrial production, cantilever cranes, as important material handling equipment, are widely used in industries such as manufacturing, logistics, and construction. They liberate workers from heavy physical labor, significantly enhancing work efficiency and operational safety. Different production scenarios and operational requirements have led to the development of various types of cantilever cranes. Now let's take a look at the types of cantilever cranes and their application scenarios, so as to choose the lifting equipment that suits you.

Common types

Fixed-column cantilever crane

This is the most common type, consisting of a column fixed to the ground and a rotatable cantilever. Simple structure, high stability and low maintenance cost; After installation, it does not need to be moved frequently and is suitable for long-term fixed operations. The lifting capacity range is wide, from several hundred kilograms to tens of tons, all can be customized.

Wall-mounted cantilever crane

The cantilever beam is fixed to a load-bearing wall or a column of the factory building, and the cantilever can rotate around the fixed point. It can be directly installed on the wall to save floor space. Compact structure, does not affect the layout of other equipment; It is firmly installed and suitable for efficient lifting in medium-sized Spaces. The length and height of the cantilever can be adjusted as needed to adapt to different material handling heights and ranges.

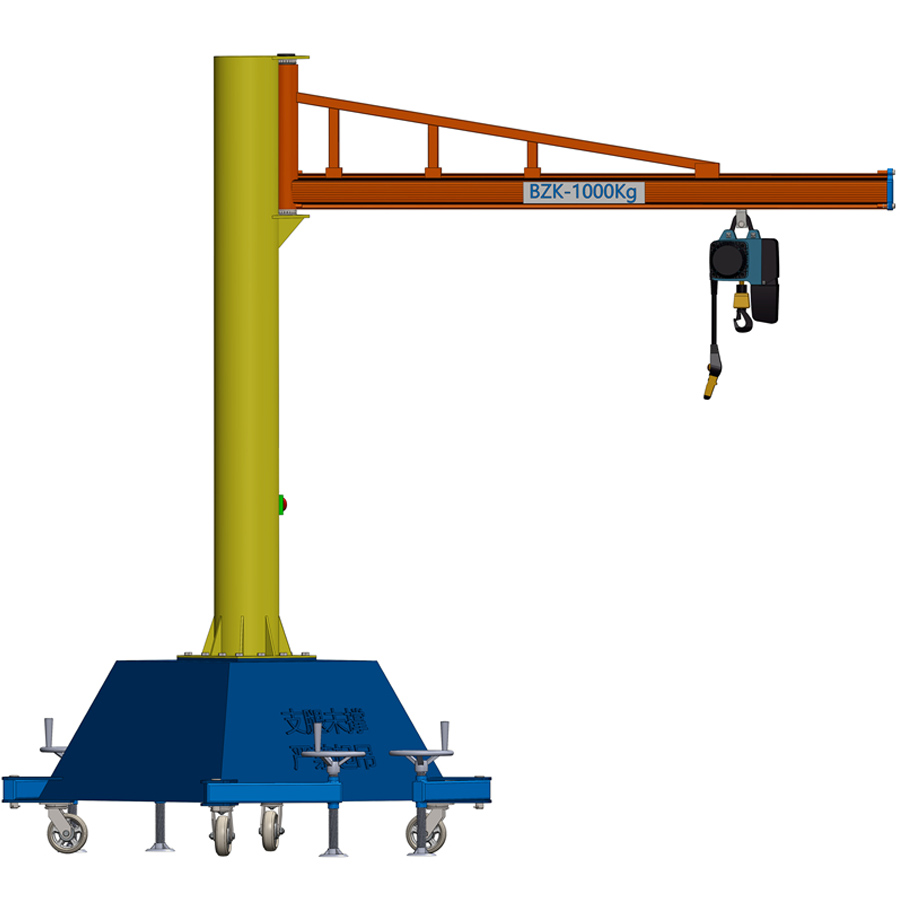

Mobile cantilever crane

The cantilever crane was installed on a mobile chassis with wheels, making it a movable lifting unit. It is equipped with wheels at the bottom, allowing for quick movement to different work locations. It is easy to operate, highly adaptable and can cover a wide range of working areas. No complex installation is required, saving time and cost.

Different types of application scenarios

column cantilever crane

It is suitable for places with fixed locations, compact Spaces and frequent lifting operations, such as material handling on production lines, equipment maintenance points, assembly lines and other workshops for material loading, unloading and assembly operations.

Wall-mounted jib crane

Applicable scenarios: Work in the corners or narrow areas against walls of workshops and warehouses with limited ground space, such as small mechanical processing plants and logistics centers.

Wall-mounted cantilever crane

Applicable scenarios: It is suitable for serving a long production line or assembly line. The lifting points can cover the entire line, making it very economical and efficient for lifting needs with irregular positions.

Mobile jib crane

Applicable scenarios: Large warehouses, maintenance workshops, construction sites, etc. where the storage locations of goods are not fixed, and temporary lifting operations need to be carried out by flexibly adjusting the lifting point locations.

How to choose the right Jib crane

Lifting capacity

Determine the maximum weight of the items that need to be lifted. The rated lifting capacity of the selected cantilever crane must be greater than this weight, and a certain safety margin should be reserved (for example, if the maximum load is 1 ton, it is recommended to choose a 1.5-ton or 2-ton cantilever crane model).

Working radius

Determine the radius of the circular or fan-shaped area to be covered so that it does not come into contact with the surrounding facilities during the rotation process. The rotation radius of the cantilever crane must be able to cover the farthest point of this area.

Lifting height

Determine the required height: The vertical distance from the ground to the lowest point of the hook needs to meet your work requirements and leave some space to smoothly lift and place the workpiece.

Operation mode

For light load and low frequency, manual push of the cantilever rotation and hand chain hoist can be selected to meet the usage requirements, with low cost. For heavy loads and high frequency, choose the model with electric rotary and chain hoists, which makes operation more effortless, efficient and precise.

1

If the ground space is spacious and unobstructed, the fixed column type is the best choice.

2

If the work area is close to the wall, the wall-mounted layout can save floor space.

3

If the lifting location changes frequently, mobile is the only option.

Tips

In addition to the several common types introduced in this article, Jib crane manufacturers also have other types of cantilever cranes. If there are special environmental requirements, explosion-proof cantilever cranes and explosion-proof hoists should be selected for explosion-proof areas. For outdoor use, protection levels such as wind resistance and rain resistance should be considered. When choosing a cantilever crane, enterprises can comprehensively consider factors such as their own production needs, site conditions, and budget, organize and customize parameters, and submit them to suppliers to ensure that they select the most suitable equipment for themselves.